Matakan sarrafa sapphire na yau da kullun a cikin masana'antar mu sune kamar haka:

X-Ray NDT Crystal daidaitacce na'urar

Na farko, za mu yi amfani da crystal fuskantarwa kayan aiki don gano crystal fuskantarwa, sa'an nan za mu alama fuskantarwa a matsayin abokin ciniki ta buƙatun.

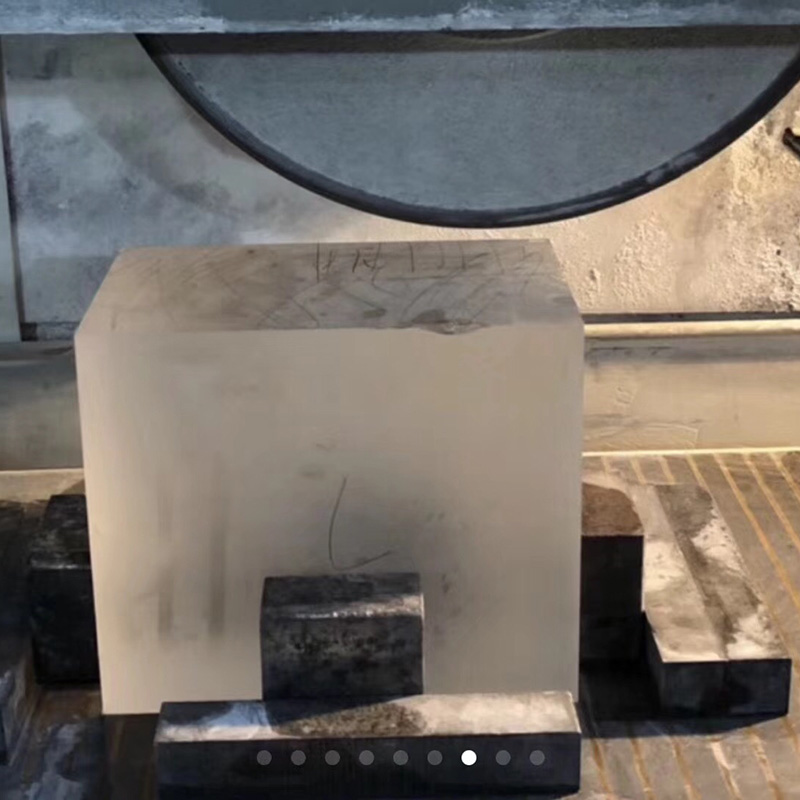

Sapphire Brick Yanke

Sa'an nan kuma za mu yanki bulo na sapphire, kauri yana kusa da samfurin da aka gama, amma ajiye kauri na cirewa da ake buƙata don niƙa da gogewa.

Injin Zagaye

Idan samfurin ƙarshe ya kasance siffar zagaye, to, za mu zagaye da yanke square ko zagaye lebur takardar don kawo zagaye na samfurin zuwa matakin da ake bukata.

Dakin Nika

Bayan kammala duk aikin da ya gabata a kan siffar, za mu sarrafa saman samfurin daga niƙa,Dangane da girman buƙatar daidaiton mashin ɗin, muna amfani da matakai daban-daban guda biyu, niƙa mai gefe ɗaya ko niƙa mai gefe biyu.

Single-gefe nika & polishing inji

Niƙa mai gefe guda ɗaya yana ɗaukar tsayi kuma ya dace da samfuran tare da buƙatun saman ƙasa

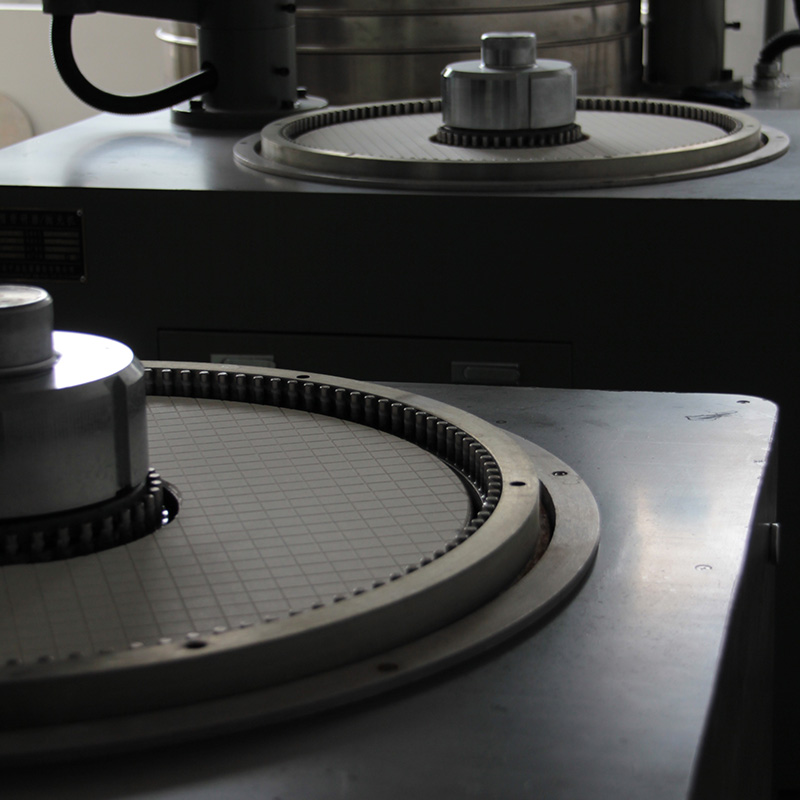

Injin niƙa mai gefe biyu

sarrafa niƙa mai gefe biyu yana da sauri fiye da niƙa na gefe ɗaya, yana iya kammala niƙa saman biyu a lokaci guda, kuma daidaiton samfurin na niƙa mai gefe biyu ya fi wannan niƙa mai gefe guda.

Manual Chamfering

Chamfering na iya guje wa mummunan tasirin rugujewar gefe akan niƙa da gogewa a cikin aiwatar da mashin ɗin.,Hakanan yana kare ma'aikata daga yanke lokacin jigilar kayayyaki.

Fine nika aiwatar workpiece

Bayan kammala aikin niƙa na farko, zai shiga cikin niƙa na biyu, tsarin niƙa mai kyau

Auna Kauri

Lokacin da aikin niƙa mai kyau ya cika, muna buƙatar auna kauri kuma tabbatar da cewa yana cikin juriya na ƙãre samfurin. Kauri ba zai canza ba yayin aiwatar da gogewa, don haka kauri bayan niƙa mai kyau ya kamata ya kasance cikin buƙatun da aka gama.

Dakin goge baki

Idan saman ingancin samfurin nika mai kyau na iya wuce binciken ƙwararrun ma'aikatanmu, to, ya shiga matakin ƙarshe na aiki, gogewa. Daidai da nika, za mu yi amfani da biyu daban-daban polishing hanyoyin dangane da abokin ciniki ta surface ingancin bukatun.

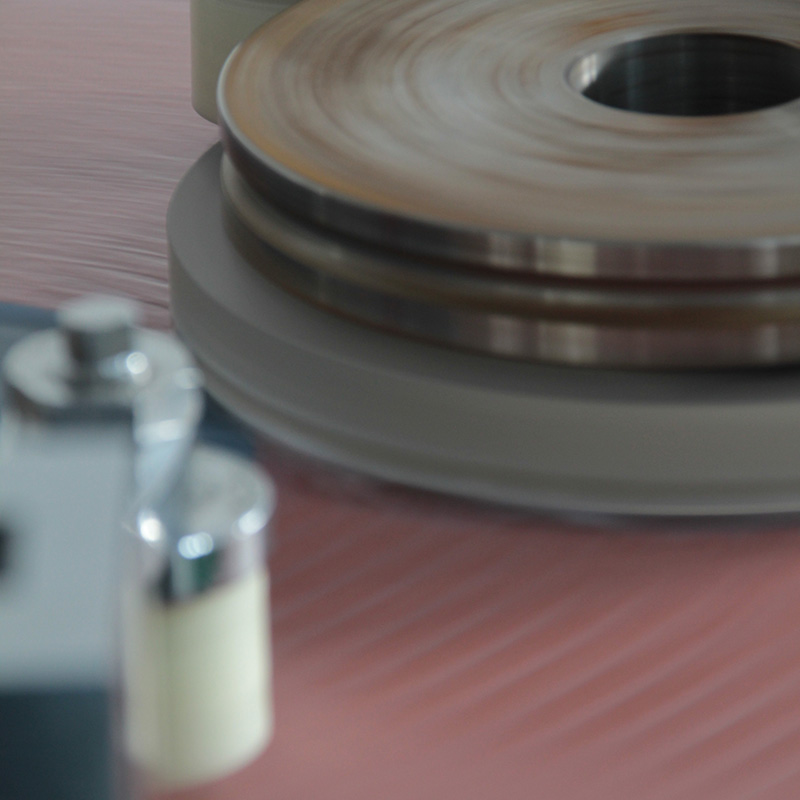

Dakin gogewa Biyu Da Kayan Aikin Ruwa

Biyu-gefe polishing iya ƙwarai rage lokacin da ake bukata domin polishing, yayin da kawar da aiki matakai na m farantin, don haka shi ne yawanci amfani da surface ingancin bukatun ba high, amma da aiki yawa ne babba.

Gyaran Gefe Guda Daya

Don samfuran da ke da buƙatun inganci masu inganci, sau da yawa ya zama dole don aiwatar da gefe ɗaya akan na'urar polishing mai gefe guda ɗaya don rage sauye-sauyen da ke buƙatar sarrafawa a cikin tsarin sarrafawa, kuma nau'ikan madaidaicin madaidaicin sau da yawa suna buƙatar daidaitawa kuma ana sarrafa su akai-akai don samun, wanda kuma ke ƙayyade dalilin da yasa farashin ingantattun samfuran ya fi girma daidai da ainihin samfurin.

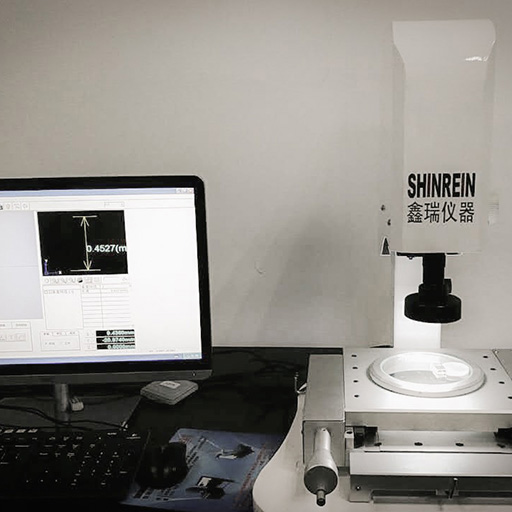

Duban Girma

Bayan sarrafawa da tsaftacewa, ana aika samfurin zuwa cibiyar binciken ingancin mu don jerin gwaje-gwaje don tabbatar da cewa samfurin da aka gama ya cika buƙatun ƙirar abokin ciniki. Tabbas, gwajin samfurin da aka gama anan baya wakiltar duk hanyoyin gwajin mu da ma'anar tabbacin inganci, Gwajin samfur zai gudana cikin dukkan tsari.,yafi kamar Girma, roundness, parallelism, verticality, angle, surface flatness.

Tabbatar da ingancin saman

Muna amfani da daidaitattun fitilun dubawa da na'urori masu ƙima don bincika tabo da tabo a saman samfurin.

Duba Lalacewar Sama

Za a gano shimfidar fili da daidaiton samfurin ta amfani da interferometer na Laser